15

2025

-

01

Laser cutting is a high-precision cutting technology that uses a focused laser beam to cut materials such as metal, plastic, wood, and glass.

The advantages of laser cutting technology are numerous. It allows for extremely precise cuts with minimal material waste, as the laser beam is capable of cutting complex shapes with tight tolerances. The process is also fast and efficient, with high cutting speeds and the ability to cut multiple layers of material at once. Laser cutting is a non-contact process, meaning there is no physical force applied to the material, resulting in clean, burr-free edges. Additionally, laser cutting is a versatile technique that can be used on a wide range of materials and thicknesses.

Author:

Laser cutting is a high-precision cutting technology that uses a focused laser beam to cut materials such as metal, plastic, wood, and glass. The principle of laser cutting is based on the interaction between the laser beam and the material being cut.

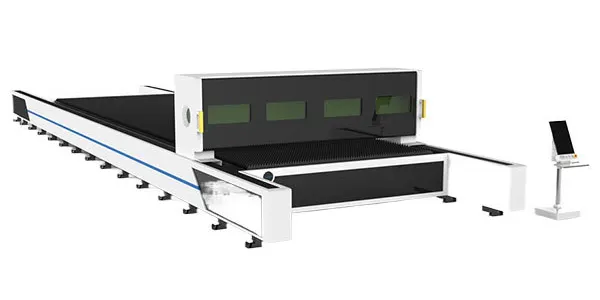

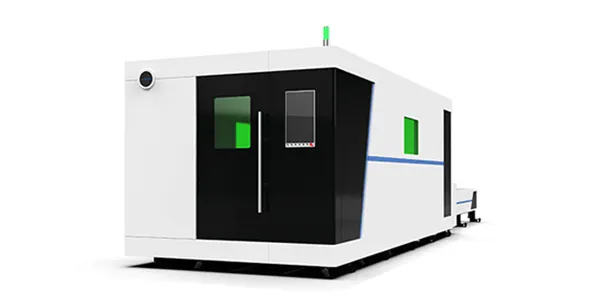

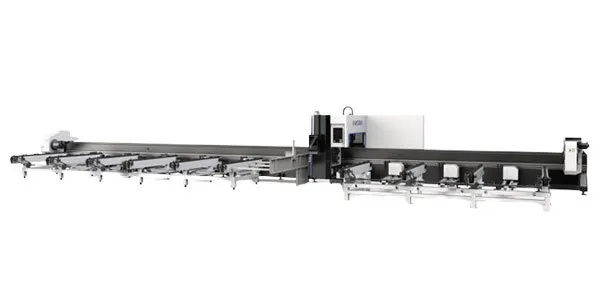

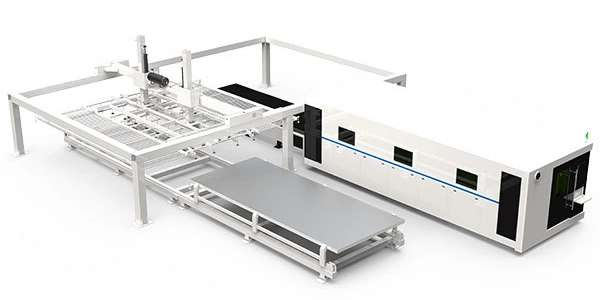

The key components of a laser cutting system include a laser source, a focusing lens, a cutting head, a workpiece table, and a control system. The laser source emits a high-energy beam of light, which is focused by the lens into a small, intense spot on the surface of the material. The cutting head then moves the focused beam along the desired cutting path, melting and vaporizing the material as it goes. The molten material is blown away by a jet of gas, leaving a clean, precise cut.

There are two main types of lasers used in cutting applications: CO2 lasers and fiber lasers. CO2 lasers are gas lasers that emit a wavelength of 10.6 microns, which is well-suited for cutting non-metallic materials such as plastics, wood, and fabrics. Fiber lasers, on the other hand, use a solid-state medium to generate a laser beam with a wavelength of 1.06 microns, making them ideal for cutting metals such as steel, aluminum, and copper.

The advantages of laser cutting technology are numerous. It allows for extremely precise cuts with minimal material waste, as the laser beam is capable of cutting complex shapes with tight tolerances. The process is also fast and efficient, with high cutting speeds and the ability to cut multiple layers of material at once. Laser cutting is a non-contact process, meaning there is no physical force applied to the material, resulting in clean, burr-free edges. Additionally, laser cutting is a versatile technique that can be used on a wide range of materials and thicknesses.

However, there are also some limitations to laser cutting. The initial cost of a laser cutting system can be high, making it less accessible for small businesses or hobbyists. Certain materials, such as reflective metals or highly transparent materials, may not be suitable for laser cutting due to their ability to reflect or absorb the laser beam. Additionally, the heat generated by the laser beam can cause thermal distortion or discoloration of the material being cut, particularly in thicker materials.

In conclusion, laser cutting is a highly versatile and precise cutting technology that offers many advantages over traditional cutting methods. By understanding the principles of laser cutting and its capabilities, manufacturers and fabricators can harness the power of this technology to create intricate and high-quality products. As laser cutting technology continues to advance, it is likely to become an increasingly important tool in the world of manufacturing and fabrication.

Related news

2025-03-12

Contact Us

E-mail:info@haisinn.com

WhatsApp: +86-19546137663

Tel: +86-19546137663

Address:No. 57 Industrial South Road, High tech Zone, Jinan, China

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.